Organic 3D Printed Materials:

Testing and Analysis

at Thayer School of Engineering

June - August 2018

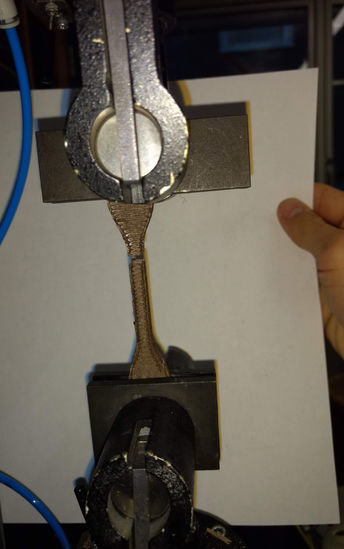

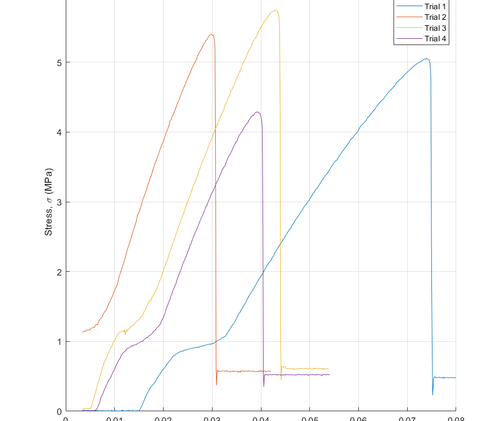

In a group with three other students, novel organic materials that could be pneumatically 3D printed were tested and analyzed. Some samples were cast instead of printed. This included tensile testing and scanning electron microscopy at the break site of each tested sample.

My role in the project included performing the tensile testing on all samples, creating the stress-strain curves, analyzing those curves, and writing much of the resulting report, including the entirety of the introduction. I organized most of the project, overseeing scheduling and logistics, and was trained on the operation scanning electron microscope for better understanding during analysis.

Below you can find pictures of the broken dog bone samples from tensile testing, a few stress-strain curves.

You can find the paper in PDF form here. I wrote the entirety of the introduction, made all stress-strain curves, and contributed to the results and discussion, as well as parts of the conclusion.

An Instron used to create stress-strain curves.

The Final Report

Below, samples and tensile testing is shown. Click for detail.

Below, a sample stress-strain plot and SEM images. Click for detail.